Fused Deposition Modeling

- Uses two kinds of materials, a modeling material and a support material.

- Modeling material: used to create the printed object and the support material acts as a scaffolding to support the object when it is being printed

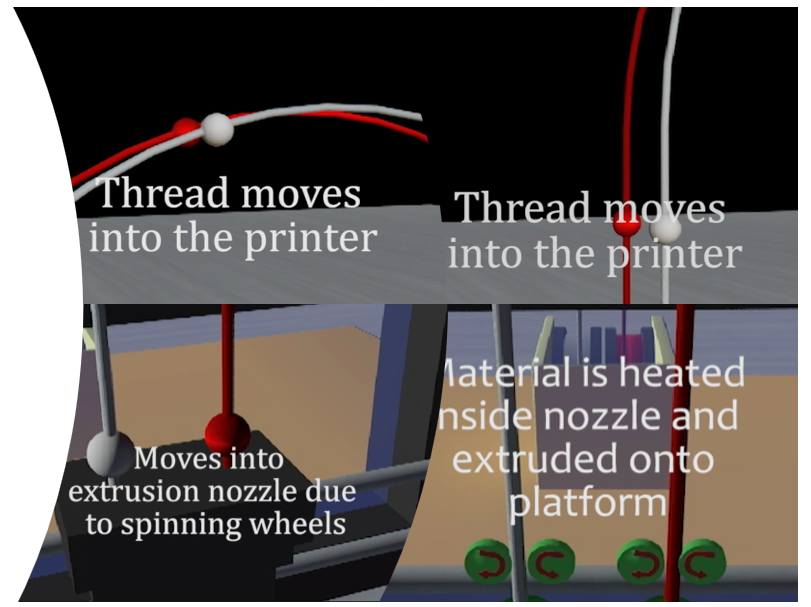

- Generally, the materials in the form of long threads or filaments move through the spinning wheels and are fed into an extrusion nozzle

- The nozzle melts the material and extrudes it onto a base (also known as the build platform/table)

Fused Deposition Modelling Process

- An FDM printer creates an object layer by layer. The layers are placed on top of one another as either the nozzle or the build platform moves up and down

- Material drawn through a nozzle, where it is heated & deposited layer by layer. Nozzle can move horizontally & platform moves up and down vertically after each layer is deposited

- After all the layers are printed (one over the another), the object is allowed to cool off ; then layers fuse & harden

- Finally, the support material is pulled from the object

Build Materials

- Build and support materials are available in the form of a filament that are rolled on spools.

- 3D models with FDM can be made with different materials including

- Acrylonitrile Butadiene Styrene (ABS) plastic

- Medical grade ABS thermoplastic

- Elastomer

- Casting Wax

FDM Process Video

FDM Process Graphic

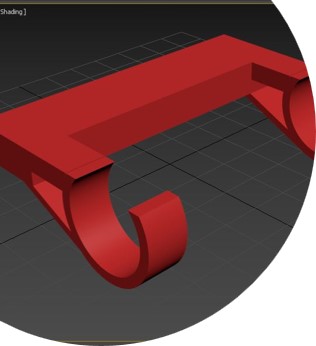

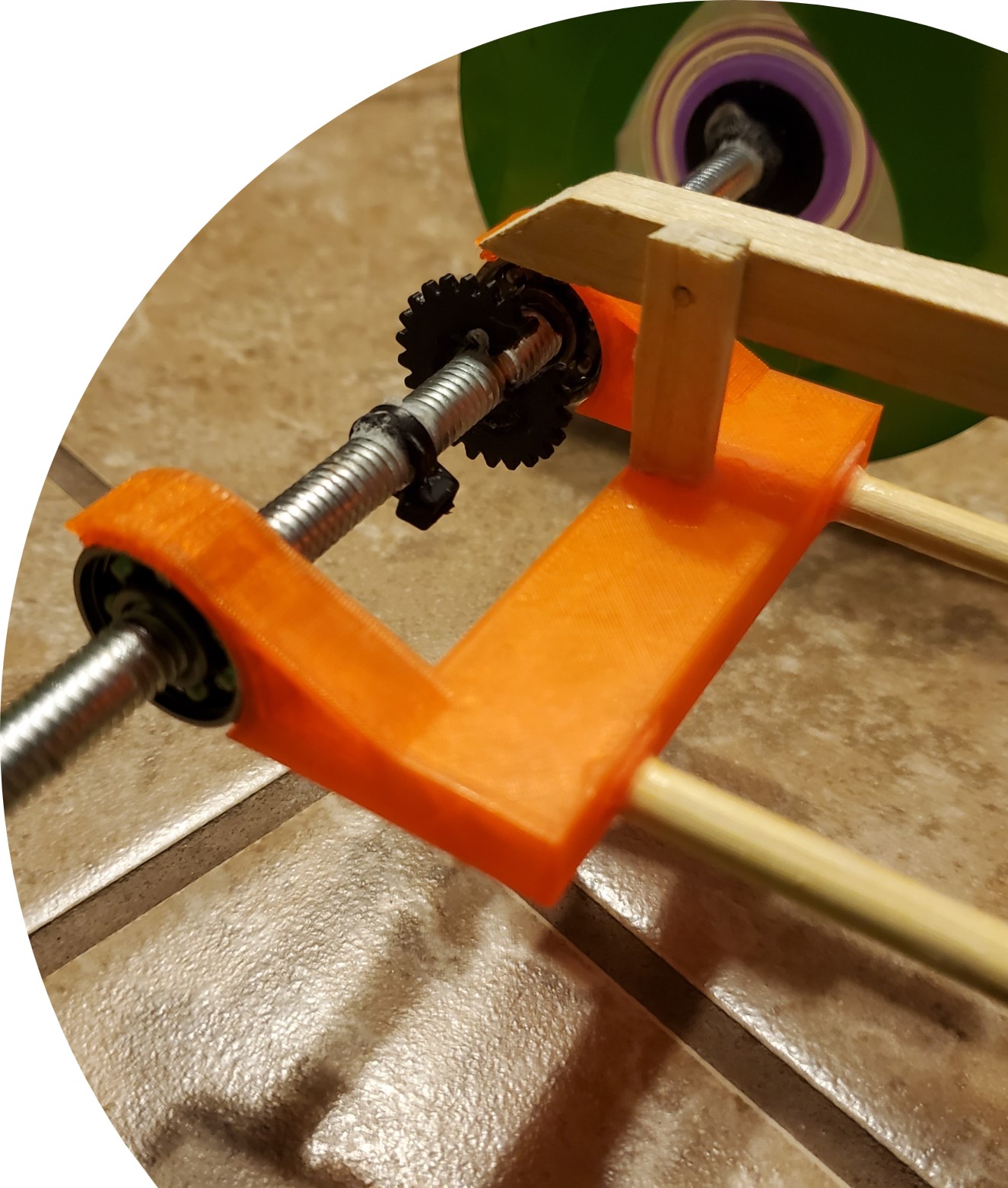

3D Model STL Printer Software (Ultimaker Cura) Final 3D Printed Model

Applications

- Large scale industrial applications as well as simple in-home and educational applications

- Creality CR-10 S